Collimators

Collimators are optical systems used to imitate standard targets placed in "optical infinity" (very long distance). The collimators are used for projection of image of reference targets into direction of tested imagers. According to type of optical elements used in design, collimators are divided into two groups: reflective collimators and refractive collimators. Reflective collimators due to their wide spectral range are almost exclusively used in systems for testing thermal imagers and are also preferable in systems testing TV cameras, SWIR imagers, laser systems or multi-sensor surveillance systems. Refractive collimators are mostly used in systems for testing night vision devices or TV cameras working in visible/near infrared range.

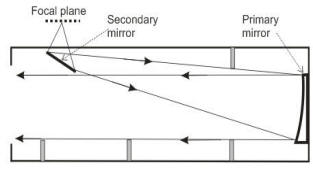

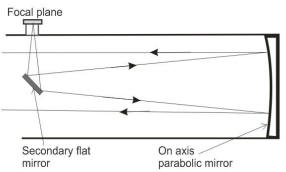

From optical designer view, the reflective collimators are inverted telescopes. Therefore it can be claimed that there are many types of reflective collimators depending on mirrors configurations (Newton, Cassegrain, Schwarzschild, Maksutov, etc). However, practically reflective collimators are typically built using Newton design (big parabolic primary, collimating mirror and smaller secondary flat mirror). Next, the reflective collimators can be divided into two basic types: off axis collimators and on-axis collimators.

Off axis reflective collimators offers un-obstructed aperture because the secondary mirror is located outside collimator aperture (Fig.2). However, off axis reflective collimators are also more costly than reflective on axis collimators. Low cost symmetric parabolic mirrors are used to design on-axis reflective collimators. Non symmetric mirrors (parts of a bigger mother symmetric mirror) are needed in case of off axis collimators. Next, aligning of off-axis collimators is more difficult than in case of typical on axis collimators. Inframet manufactures a long series of CDT off axis reflective collimators that are used as blocks of Inframet test systems or sold as independent optical modules.

|

|

| Fig. 1. A series of CDT collimators of different apertures and focal lengths | Fig. 2. Optical diagram of an off axis collimator |

The on-axis collimators have a dead area in center of their optical aperture due to presence of a non transmitting, secondary mirror. This feature limits significantly applications of on axis collimators in systems for testing imagers of big optics. There is a risk that the dead area of the on-axis collimator can make optics of tested imager only partially working and influence measurement results. However, these collimators are fully acceptable in boresight test systems or when on-axis mirror is so big that that there is no overlapping of dead area of the collimator and optics of tested imagers. CJT collimators manufactured by Inframet and used in JT boresight systems and in MIS systems for testing multi-sensor surveillance systems belong to this group.

|

|

| Fig. 3. CJT20100 collimator | Fig. 4. Optical diagram of an on axis collimator |

Inframet typically deliver collimators for a vertical configuration test systems (blackbody, wheel and targets are on the collimator) due to better thermal stability of such test systems (important when testing high-tech thermal imagers -> see paper). However, Inframet can deliver collimators for a horizontal configuration test systems (blackbody, wheel and targets are at the same horizontal level as the collimator). Typical apertures of off axis collimators are as high as 300 mm, but optionally Inframet can deliver off axis collimators of apertures as high as 500mm.

Data sheets:

- CDT off axis collimators

- CJT on axis collimators