Targets

Targets are modules that can create image of reference patterns needed when testing electro-optical imaging systems. The targets manufactured by Inframet can be divided into two groups:

- Passive targets,

- Active targets.

The passive targets need to be irradiated by a uniform beam of light generated by blackbodies or calibrated light sources in order to create images of reference image patterns. These targets are typically small modules of bigger test systems and are located at collimator focal plane. The passive targets do not need electric power for proper work. These are typically small size targets ( diameter below 100mm for IR targets/ VIS targets and below 300mm for case of NV targets) that are used as part of big modular test systems manufactured by Inframet (DT, TAIM, TVT, MS). They are typically inserted into holes of a rotary wheel. Image of the passive target is projected by a collimator.

Fig. 1. Photo of an exemplary passive target: IR target of 4-bar pattern

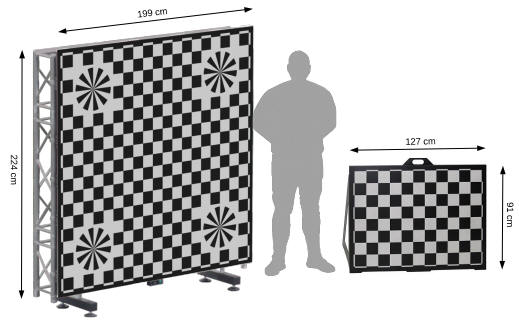

The active targets create images of reference image patterns due to their own thermal radiation or due to reflected light emitted by sources typically met in human environment. These targets are typically big stand alone modules (dimensions from 500mm to 3000mm) that need electric power for proper work. The active targets are typically used as stand alone blocks that are directly seen by tested EO imagers. These target are popular solution for testing fusion algorithms of fused imagers or as resolution targets of thermal imagers/VIS-NIR cameras. FUT series targets are an example of this type of targets.

Fig. 2. Photos of two exemplary active targets

The passive targets can be divided according to application on three groups:

- Infrared targets (IR targets),

- Visible targets (VIS targets),

- Night vision targets (NV targets).

The IR targets are used for testing thermal imagers operating at MWIR-LWIR spectral band. VIS targets are used for testing color VIS cameras, monochromatic VIS-NIR cameras, or VIS-SWIR cameras operating in VIS-SWIR spectral band. NV targets are used for testing nigh vision devices operating in VIS-NIR spectral band. These three group of targets differ due to manufacturing technology even if both VIS targets and NV targets work in similar spectral band.

Data sheets:

- Infrared targets (IR targets),

- Visible targets (VIS targets),

- Night vision targets (NV targets),

- Active targets.