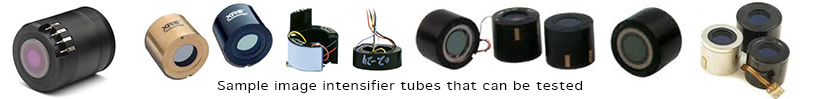

Image intensifiers

Image intensifier tubes (IITs) are vacuum tubes that amplify a low light-level image to observable levels. Image intensifier tubes are the most important modules of night vision devices that play crucial role in defense/security/industrial applications. Technology of manufacturing of image intensifier tubes is very difficult and performance parameters of modern IITs varies even within the same technological process. Next, test report offered by manufacturers cannot be fully trusted because there are some differences in test methods used by different manufactures. Further on, there are literature sources presenting conflicting claims of different manufacturers. It is quite common to find on the world market two night vision devices (or two image intensifier tubes) of the same data sheet parameters but of different image quality. Inverse situation is possible, too. Due to reasons mentioned above testing image intensifier tubes is of critical importance for both their manufacturers, manufacturers of night vision devices (NVDs) and final users of NVDs.

Testing of image intensifier tubes is typically done according to methods recommended by US MIL standards. These test methods refer to testing potted tubes after encapsulation. There are however some projects when more detail testing is needed using non-MILs methods or bare tubes before encapsulation are to be tested.

Inframet offers a series of test stations/systems: ITIP, ITR, IPAS, IMAG, IBIG.

ITIP is the main Inframet station for testing typical (photocathode below 25mm, spectral band: VIS-NIR) image intensifier tubes. It is a quasi universal computerized station that enables measurement imaging,photometric, electrical and temporal parameters of of image intensifier tubes.This new test station replaces old ITS-I, ITS-IP, ITS-P test stations manufactured by Inframet until middle of 2017 year.

ITR station enables measurement of reliability parameters of tubes. IPAS enables testing performance of miniaturized HV power supplies used to built modern image intensifier tubes.

IBIG enables testing non-typical (large photocathode or non typical spectral band) image intensifier tubes.

IMAG is a revolutionary system that enables automatic testing of typical image intensifier tubes to support mass manufacturing.

|

|

|

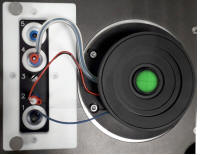

| Fig.1 ITIP test station | Fig.2 ITR test station | Fig.3 IPAS test station |

Optional tools

|

The HVP14C power supply is a special

computerized high voltage power supply

optimized for use in systems for testing

bare image intensifier tubes. It is

built as set of of four HV power

modules: HVP-1 to power photocathode

circuit, : HVP-2 to power MCP circuit,

HVP-3 to power screen circuit, and HVP-4

– an option for some Gen3 tubes when

voltages higher than 6000 V are needed.

The HVP14C power supply differ significantly from typical laboratory high voltage power supplies. All channels are separated from each other and input power supply. Next, the voltage regulation ranges are optimized for testing bare image intensifier tubes. Finally, HVP14C can be controlled from a PC set using ethernet port. HVP14C is optimized for use in semi automatic station for testing of bare image intensifier tubes. HVP14C power supply is especially useful for manufacturers of II tubes who want to automatically determine a set of optimal voltages for powering bare II tube in order to achieve best MTF function of such tube. |

HVP14C computerized high voltage power supply |

Market situation

Inframet is the top world leader in equipment for testing image intensifier tubes. A series of well known manufacturers of II tubes or manufacturers of night vision devices use Inframet test stations to improve quality control of their products. Other important group of our customers are scientific institutes doing research in field of image intensifier tubes.

Learn more:

- Data sheets: ITIP, ITR, IPAS, IBIG, IMAG, HVP14C

- Scientific paper ->Review of night vision technology (sample part)

- Scientific paper ->Computerized station for testing image intensifier tubes

- Recommendations on environmental conditions for Inframet test systems

- Manual of Nightmet simulator

- Nightmet simulator

- Educational section

- Info section

- Newsletter

- Contact INFRAMET